Copper cathodes play a crucial role in the production of copper-based products used in various high-quality applications. With their high purity and excellent conductivity, they are sought after in industries such as electrical wiring, manufacturing of copper rods, and the production of alloys like bronze. In this article, we will explore the process of these production, their properties, and their significance in various industries.

What are Copper Cathodes?

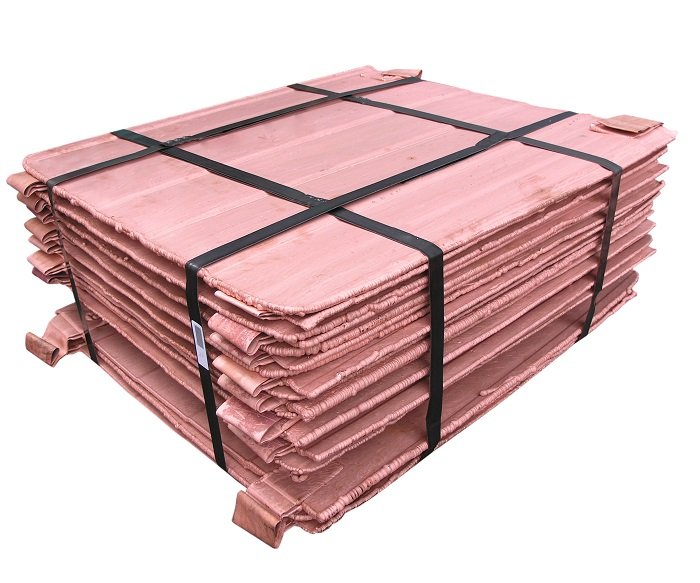

They are square-shaped plates of copper that have a purity level of at least 99.95%. They are produced through the electrolytic refining process, where pure copper separates from unwrought copper. Companies like Aurubis and Hindalco are renowned for their production of minerals with exceptional quality and purity. These cathodes are widely used due to their high conductivity and low impurity levels.

Copper Cathode Production Process

The production of this minerals involves several stages, starting from the extraction of copper ore. One of the most common types of copper ore is chalcopyrite, which is a mixture of copper, iron, and sulfur. After the ore is mined, it undergoes a smelting process, where it is heated to high temperatures to separate the copper from other elements.

During smelting, oxygen reacts with the iron in the ore, resulting in the formation of iron oxide, sulfur dioxide, and copper sulfite. The copper sulfite, also known as copper matte, is then exposed to high levels of oxygen to further remove impurities and increase purity. This molten copper matte undergoes electrolytic refining to produce items with a purity level of 99.99%.

In the electrolytic refining process, the copper matte is subjected to a weak acid solution, leading to the formation of a copper sulfate solution. This solution is then treated and transferred to an electrolytic process tank. Through the application of electric current, pure copper ions migrate from the solution to starter cathodes made from pure copper foil. This deposition process continues until a 300-pound cathode is formed, with a purity level of 99.9%.

Properties of Copper Cathodes

They possess several properties that make them highly desirable in various industries. Firstly, their high purity level ensures excellent conductivity, making them ideal for electrical wiring applications. The low impurity levels, including trace amounts of minerals like nickel, silver, and gold, contribute to the overall quality and reliability of the subtance

The dimensions of this item vary depending on the manufacturer. For instance, Aurubis produces cathodes with dimensions of approximately 965mm x 975mm x 5-10mm, while Hindalco’s Birla are measure around 1 meter x 1 meter x 6mm. These dimensions allow for flexibility in their usage, whether it be for wire production, alloying, or casting purposes.

Applications of Copper Cathodes

Copper cathodes serve as the primary raw material for the production of various copper-based products. One of the significant applications is the manufacturing of continuous cast copper rods used in the wire, cable, and transformer industries. The high-grade copper cathodes ensure the production of rods with exceptional conductivity and reliability.

In addition to rod production, copper cathodes are also utilized in the manufacturing of copper tubes for consumer durable goods and other applications. These tubes find applications in industries such as HVAC, plumbing, and refrigeration. Moreover, copper cathodes can be further processed into alloys like bronze, which are used in the production of a wide range of products.

Quality Standards and Certifications

To ensure the highest level of quality and consistency, copper cathode manufacturers adhere to various quality standards and certifications. For instance, Aurubis produces cathodes that comply with the cathode standards LME Grade A, Cu-CATH-1 (EN 1978), and Copper Cathodes Grade 1 (ASTM B115). Their production sites are also certified in accordance with ISO 9001 and ISO 14001.

To ensure the highest level of quality and consistency, copper cathode manufacturers adhere to various quality standards and certifications. For instance, Aurubis produces cathodes that comply with the cathode standards LME Grade A, Cu-CATH-1 (EN 1978), and Copper Cathodes Grade 1 (ASTM B115). Their production sites are also certified in accordance with ISO 9001 and ISO 14001.

Similarly, Hindalco’s Birla Copper cathodes meet International Quality Standards such as BS 6017 1981 (1989) and u-Cath-1 / ASTM B-115 (1999). They are registered as A-Grade cathodes on the London Metal Exchange (LME), ensuring their quality and marketability.

Transportation and Handling

During transportation, it is crucial to prevent contamination of copper cathodes with extraneous materials. Manufacturers often ship copper cathodes in bundles, held together by steel strapping. Care must be taken to avoid breakage of these straps, which can result in the loss and separation of cathode sheets.

Copper cathodes are usually bought based on weight and are shipped unpacked or bound together with metal bands. It is common for cathodes to have surface irregularities, which may be further affected during transit. This can result in a difference between the shipped and delivered weights of the cathodes.

Conclusion

Copper cathodes are essential components in the production of high-quality copper-based products. Their high purity, exceptional conductivity, and low impurity levels make them ideal for various applications in industries such as electrical wiring, manufacturing of copper rods, and alloy production.

Manufacturers like Aurubis and Hindalco produce copper cathodes that meet stringent quality standards and certifications. These cathodes undergo a rigorous production process, ensuring their exceptional quality and reliability. Proper handling and transportation of copper cathodes are crucial to prevent contamination and maintain their integrity throughout the supply chain.

copper cathode/copper cathodes price

copper cathode Grade A

Purity: purity 99.97%-99.99% min

Specifications

Competitive & reliable price

Excellent customer service

Outstanding delivery reliability

- Typical SPECIFICATIONS

| Dimensions | 914mm x 914mm x 12mm | |||

| Weight per sheet | 105Kg (±1%) | |||

| Net weight per pallet | 2MT approx | |||

| Min, weight in each container | 20MT approx | |||

| Gross weight of each container | 22.2MT approx | |||

| Packaging | Palletized, Aluminum bands | |||

| elements | value | elements | value | |

| copper (min %age) | 99.99% | silica (si/ppm) | 0.3 | |

| iron (fe/ppm) | 2 | cobalt (co/ppm) | 0.2 | |

| sulphur (s/ppm) | 4 | arsenic (as/ppm) | 0.1 | |

| oxygen (o2/ppm) | nil | bismuth (bi/ppm) | 0.1 | |

| argent (ag/ppm) | 10 | manganese (mn/ppm) | 0.1 | |

| lead (pb/ppm) | 0.2 | teleurium (te/ppm) | 0.05 | |

| nickel (ni/ppm) | 0.2 | aluminium (al/ppm) | 0.5 | |

| selenium (se/ppm) | 0.3 | magnesium (mg/ppm) | 0.4 | |

| antimony (sb/ppm) | 0.1 | |||

Reviews

There are no reviews yet.